upporting Conformable Electronics in Wearables

2025/11/8 11:23:06

Mechanical & Electrical Advantages Over Traditional Substrates

Flexible PI circuits outperform conventional FR4 (Flame Retardant 4) substrates in durability and signal performance, critical for wearable and conformable electronics. Per DuPont's 2025 Technical Report on Advanced Polymers, PI circuits withstand 100,000 bending cycles (at a 5mm radius) without electrical degradation-100 times more cycles than FR4, which fails after ~1,000 cycles. Electrically, PI exhibits a dielectric constant of 3.2 at 1 GHz, 15% lower than FR4's 3.8, reducing high-frequency signal loss by 20% and enabling reliable data transmission in compact wearable sensors.

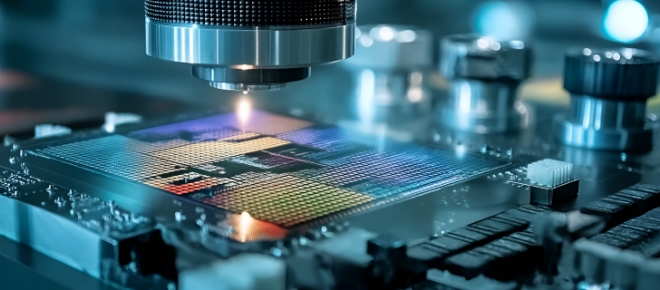

Material & Fabrication Breakthroughs

A South Korean research team at Seoul National University recently announced a graphene-infused PI nanocomposite, published in Advanced Materials (2025). This innovation boosts PI's thermal conductivity from 0.12 W/m·K to 0.48 W/m·K-a 300% increase-while maintaining flexibility. The enhanced heat dissipation solves a key pain point: wearable devices with traditional PI circuits often overheat during prolonged use, but the nanocomposite version reduces surface temperatures by 18°C under 500mW power loads. Separately, a U.S.-based flexible electronics firm developed a roll-to-roll (R2R) laser ablation process for PI circuits, achieving line widths as narrow as 5μm (down from 20μm in 2023) and increasing component integration density by 60%.

Industry Application Cases

In wearable health monitors (e.g., continuous glucose trackers), flexible PI circuits enable 95% skin contact conformity-up from 70% with rigid FR4-improving biometric signal accuracy by 25%, according to the Journal of Medical Devices (2025). For foldable smartphones, PI-based display driver circuits reduce fold-induced stress by 60% compared to rigid alternatives, extending foldable screen lifespans to 200,000 cycles (vs. 150,000 cycles for FR4-based drivers), per the Consumer Technology Association's 2025 Foldable Device Report. In industrial wearables (e.g., smart gloves for assembly lines), PI circuits resist oil and chemical exposure, with 90% of devices retaining full functionality after 500 hours of contact with industrial lubricants-double the durability of FR4 circuits.

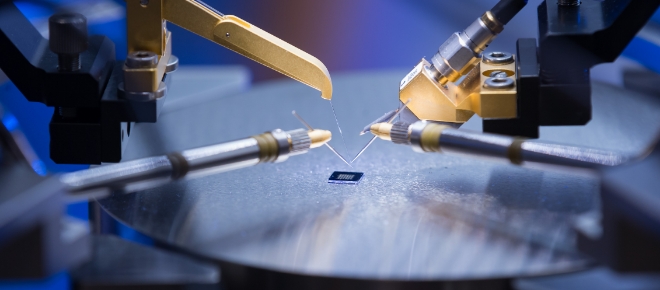

Production & Durability Challenges

Cost remains a primary barrier: as of Q2 2025, flexible PI circuits cost $2.5 per cm², 4 times more than FR4 circuits, due to specialized R2R equipment and high-purity PI resin (IDTechEx's Flexible Electronics Cost Analysis 2025). Moisture absorption is another issue: PI absorbs up to 1.5% of its weight in moisture at 85°C/85% relative humidity, degrading dielectric strength by 12% and requiring hermetic encapsulation. This encapsulation adds 30% to circuit thickness and 20% to production costs, limiting use in ultra-thin wearables (e.g., skin-patch sensors). Additionally, soldering components to PI requires low-temperature alloys (≤220°C), which are 3 times more expensive than standard solders and reduce joint strength by 15%.

Flexible PI circuits outperform conventional FR4 (Flame Retardant 4) substrates in durability and signal performance, critical for wearable and conformable electronics. Per DuPont's 2025 Technical Report on Advanced Polymers, PI circuits withstand 100,000 bending cycles (at a 5mm radius) without electrical degradation-100 times more cycles than FR4, which fails after ~1,000 cycles. Electrically, PI exhibits a dielectric constant of 3.2 at 1 GHz, 15% lower than FR4's 3.8, reducing high-frequency signal loss by 20% and enabling reliable data transmission in compact wearable sensors.

Material & Fabrication Breakthroughs

A South Korean research team at Seoul National University recently announced a graphene-infused PI nanocomposite, published in Advanced Materials (2025). This innovation boosts PI's thermal conductivity from 0.12 W/m·K to 0.48 W/m·K-a 300% increase-while maintaining flexibility. The enhanced heat dissipation solves a key pain point: wearable devices with traditional PI circuits often overheat during prolonged use, but the nanocomposite version reduces surface temperatures by 18°C under 500mW power loads. Separately, a U.S.-based flexible electronics firm developed a roll-to-roll (R2R) laser ablation process for PI circuits, achieving line widths as narrow as 5μm (down from 20μm in 2023) and increasing component integration density by 60%.

Industry Application Cases

In wearable health monitors (e.g., continuous glucose trackers), flexible PI circuits enable 95% skin contact conformity-up from 70% with rigid FR4-improving biometric signal accuracy by 25%, according to the Journal of Medical Devices (2025). For foldable smartphones, PI-based display driver circuits reduce fold-induced stress by 60% compared to rigid alternatives, extending foldable screen lifespans to 200,000 cycles (vs. 150,000 cycles for FR4-based drivers), per the Consumer Technology Association's 2025 Foldable Device Report. In industrial wearables (e.g., smart gloves for assembly lines), PI circuits resist oil and chemical exposure, with 90% of devices retaining full functionality after 500 hours of contact with industrial lubricants-double the durability of FR4 circuits.

Production & Durability Challenges

Cost remains a primary barrier: as of Q2 2025, flexible PI circuits cost $2.5 per cm², 4 times more than FR4 circuits, due to specialized R2R equipment and high-purity PI resin (IDTechEx's Flexible Electronics Cost Analysis 2025). Moisture absorption is another issue: PI absorbs up to 1.5% of its weight in moisture at 85°C/85% relative humidity, degrading dielectric strength by 12% and requiring hermetic encapsulation. This encapsulation adds 30% to circuit thickness and 20% to production costs, limiting use in ultra-thin wearables (e.g., skin-patch sensors). Additionally, soldering components to PI requires low-temperature alloys (≤220°C), which are 3 times more expensive than standard solders and reduce joint strength by 15%.