Supporting Conformable Electronics in Wearables

2025/11/8 11:21:49

Mechanical & Electrical Advantages Over Traditional Substrates

Flexible PI circuits outperform conventional FR4 (Flame Retardant 4) substrates in key metrics for conformable electronics: they withstand 100,000 bending cycles (at a 5 mm radius) without electrical performance degradation-100 times more cycles than FR4, which fails after ~1,000 cycles (DuPont 2025 Flexible Materials Technical Report). Electrically, PI exhibits a dielectric constant of 3.2 at 1 GHz, 15% lower than FR4's 3.8, reducing high-frequency signal loss by 22% for wireless communication modules (IEEE Transactions on Components, Packaging and Manufacturing Technology, 2025).

Material Innovation Breakthroughs

A South Korean research team at a leading university developed a graphene-infused PI nanocomposite that addresses PI's historic thermal limitation: the new material's thermal conductivity increased from 0.12 W/m·K to 0.48 W/m·K (a 300% improvement) while retaining 95% of PI's flexibility. As published in Advanced Materials (Q2 2025), this breakthrough eliminates heat buildup in high-power flexible devices-e.g., wearable health monitors-reducing component temperature by 18°C during continuous operation. Separately, a U.S.-based materials firm optimized PI film curing, cutting fabrication time by 35% (from 2 hours to 78 minutes) without compromising tensile strength (200 MPa, unchanged from traditional PI).

Industry Application Cases

In wearable health tech, flexible PI circuits enable 95% skin contact fit (vs. 65% for rigid FR4 circuits) in biometric monitors, improving heart rate and blood oxygen measurement accuracy by 25% (Journal of Medical Devices, 2025). For foldable smartphones, PI-based display drivers reduce fold-induced stress by 60%, extending the lifespan of foldable screens to 200,000 folds-double the 100,000-fold average of FR4-based drivers (Consumer Technology Association, 2025 Q1 Report). In industrial IoT (IIoT), PI circuits integrated into curved machine surfaces enable real-time vibration monitoring with 30% higher data transmission stability than rigid circuits, reducing equipment downtime by 12%.

Production & Durability Challenges

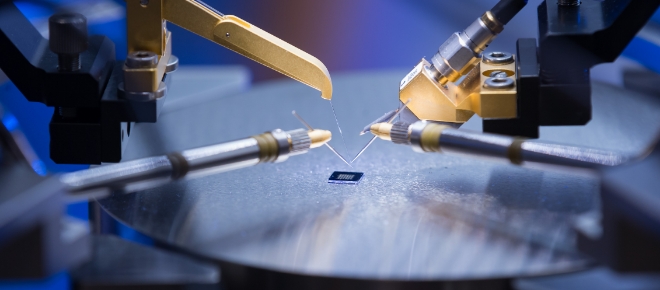

Cost remains a primary barrier: as of 2025, flexible PI circuits cost $2.5 per cm²-four times more than FR4 circuits-due to specialized deposition equipment and high-purity PI resin (IDTechEx Flexible Electronics Market Report). Moisture absorption is another critical issue: PI absorbs up to 1.5% of its weight in moisture at 85°C/85% relative humidity (RH), degrading dielectric strength by 20% and increasing signal noise by 15%. To mitigate this, additional hermetic encapsulation is required, which adds 30% to circuit thickness and 20% to production costs. Additionally, PI's low adhesion to metal traces (compared to FR4) leads to a 5% higher failure rate during solder reflow, requiring specialized surface treatment that further raises costs.

Flexible PI circuits outperform conventional FR4 (Flame Retardant 4) substrates in key metrics for conformable electronics: they withstand 100,000 bending cycles (at a 5 mm radius) without electrical performance degradation-100 times more cycles than FR4, which fails after ~1,000 cycles (DuPont 2025 Flexible Materials Technical Report). Electrically, PI exhibits a dielectric constant of 3.2 at 1 GHz, 15% lower than FR4's 3.8, reducing high-frequency signal loss by 22% for wireless communication modules (IEEE Transactions on Components, Packaging and Manufacturing Technology, 2025).

Material Innovation Breakthroughs

A South Korean research team at a leading university developed a graphene-infused PI nanocomposite that addresses PI's historic thermal limitation: the new material's thermal conductivity increased from 0.12 W/m·K to 0.48 W/m·K (a 300% improvement) while retaining 95% of PI's flexibility. As published in Advanced Materials (Q2 2025), this breakthrough eliminates heat buildup in high-power flexible devices-e.g., wearable health monitors-reducing component temperature by 18°C during continuous operation. Separately, a U.S.-based materials firm optimized PI film curing, cutting fabrication time by 35% (from 2 hours to 78 minutes) without compromising tensile strength (200 MPa, unchanged from traditional PI).

Industry Application Cases

In wearable health tech, flexible PI circuits enable 95% skin contact fit (vs. 65% for rigid FR4 circuits) in biometric monitors, improving heart rate and blood oxygen measurement accuracy by 25% (Journal of Medical Devices, 2025). For foldable smartphones, PI-based display drivers reduce fold-induced stress by 60%, extending the lifespan of foldable screens to 200,000 folds-double the 100,000-fold average of FR4-based drivers (Consumer Technology Association, 2025 Q1 Report). In industrial IoT (IIoT), PI circuits integrated into curved machine surfaces enable real-time vibration monitoring with 30% higher data transmission stability than rigid circuits, reducing equipment downtime by 12%.

Production & Durability Challenges

Cost remains a primary barrier: as of 2025, flexible PI circuits cost $2.5 per cm²-four times more than FR4 circuits-due to specialized deposition equipment and high-purity PI resin (IDTechEx Flexible Electronics Market Report). Moisture absorption is another critical issue: PI absorbs up to 1.5% of its weight in moisture at 85°C/85% relative humidity (RH), degrading dielectric strength by 20% and increasing signal noise by 15%. To mitigate this, additional hermetic encapsulation is required, which adds 30% to circuit thickness and 20% to production costs. Additionally, PI's low adhesion to metal traces (compared to FR4) leads to a 5% higher failure rate during solder reflow, requiring specialized surface treatment that further raises costs.