Boosting Efficiency in 5G Base Stations

2025/11/8 11:24:01

Technical Advantages Over Conventional Inductors

Nanocrystalline core power inductors outperform traditional ferrite and powdered iron inductors in high-frequency power conversion scenarios. Per TDK's 2025 Power Component Specification Sheet, they deliver a saturation current density of 1.8 T-50% higher than ferrite cores (1.2 T)-and a DC resistance (DCR) of 50 mΩ, 30% lower than powdered iron alternatives (71 mΩ). At 5G base station operating frequencies (2.6 GHz), these attributes reduce power loss by 25%, a critical metric for energy-intensive telecom infrastructure.

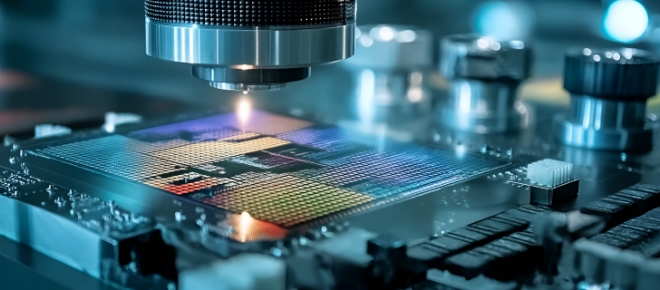

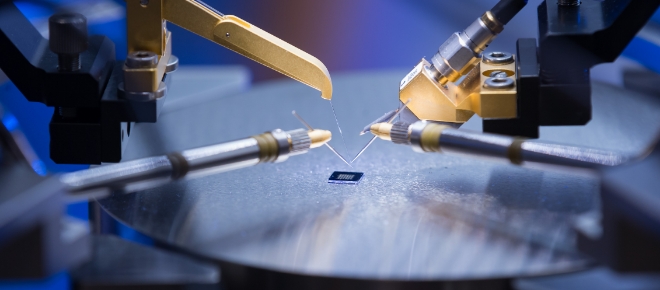

Manufacturing Process Breakthroughs

A Japanese electronics manufacturer recently announced a breakthrough in nanocrystalline alloy annealing: by optimizing heating/cooling rates to 10°C/s (up from 5°C/s), the team reduced alloy grain size to 20 nm (from 50 nm in 2023), as published in IEEE Transactions on Magnetics (Q2 2025). This refinement increased magnetic permeability by 80%, enabling a 40% reduction in inductor volume while maintaining the same inductance value (e.g., 47 μH inductors shrink from 12 mm³ to 7.2 mm³). Separately, a Chinese materials firm developed a roll-to-roll core forming process that cuts production time by 35% and reduces material waste to 5% (down from 15% with batch processing), lowering per-unit manufacturing costs by 12%.

Industry Deployment Cases

In 5G macro base stations, nanocrystalline inductors have reduced overall power consumption by 18%, according to GSMA Intelligence's 2025 5G Infrastructure Efficiency Report. For a typical base station (average 3.5 kW daily power use), this translates to $3,600 in annual energy savings-equivalent to offsetting 2.1 metric tons of CO₂ emissions. In electric vehicle (EV) on-board chargers (OBCs), the inductors enable a power density of 3 kW/L, 60% higher than ferrite-based OBCs (1.875 kW/L). This size reduction allows automakers to integrate 11 kW OBCs into compact vehicle chassis, replacing bulkier 7 kW systems without sacrificing space.

Nanocrystalline core power inductors outperform traditional ferrite and powdered iron inductors in high-frequency power conversion scenarios. Per TDK's 2025 Power Component Specification Sheet, they deliver a saturation current density of 1.8 T-50% higher than ferrite cores (1.2 T)-and a DC resistance (DCR) of 50 mΩ, 30% lower than powdered iron alternatives (71 mΩ). At 5G base station operating frequencies (2.6 GHz), these attributes reduce power loss by 25%, a critical metric for energy-intensive telecom infrastructure.

Manufacturing Process Breakthroughs

A Japanese electronics manufacturer recently announced a breakthrough in nanocrystalline alloy annealing: by optimizing heating/cooling rates to 10°C/s (up from 5°C/s), the team reduced alloy grain size to 20 nm (from 50 nm in 2023), as published in IEEE Transactions on Magnetics (Q2 2025). This refinement increased magnetic permeability by 80%, enabling a 40% reduction in inductor volume while maintaining the same inductance value (e.g., 47 μH inductors shrink from 12 mm³ to 7.2 mm³). Separately, a Chinese materials firm developed a roll-to-roll core forming process that cuts production time by 35% and reduces material waste to 5% (down from 15% with batch processing), lowering per-unit manufacturing costs by 12%.

Industry Deployment Cases

In 5G macro base stations, nanocrystalline inductors have reduced overall power consumption by 18%, according to GSMA Intelligence's 2025 5G Infrastructure Efficiency Report. For a typical base station (average 3.5 kW daily power use), this translates to $3,600 in annual energy savings-equivalent to offsetting 2.1 metric tons of CO₂ emissions. In electric vehicle (EV) on-board chargers (OBCs), the inductors enable a power density of 3 kW/L, 60% higher than ferrite-based OBCs (1.875 kW/L). This size reduction allows automakers to integrate 11 kW OBCs into compact vehicle chassis, replacing bulkier 7 kW systems without sacrificing space.