Enabling Precise Navigation in Autonomous Systems

2025/11/8 11:20:32

Technical Superiority to Conventional Sensors

MEMS IMUs (Inertial Measurement Units) with 6-axis configuration-integrating 3-axis gyroscopes and 3-axis accelerometers-deliver significant performance gains over traditional mechanical or fiber-optic alternatives. Per STMicroelectronics' 2025 Product Datasheet, these devices achieve a bias instability of 0.1°/hr, a 90% reduction compared to mechanical gyroscopes, and operate at just 5 mW of power-80% lower than fiber-optic IMUs. This combination of precision and energy efficiency makes them ideal for battery-powered or space-constrained systems.

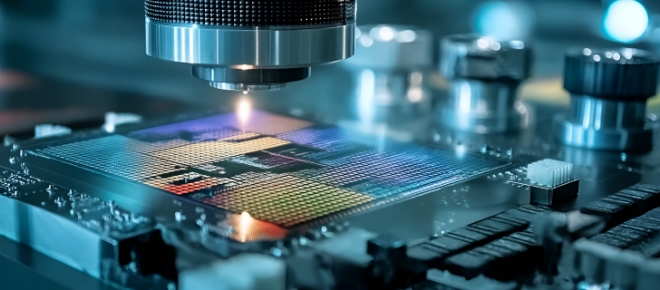

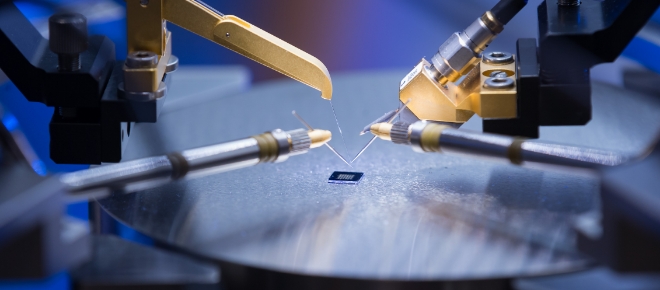

Design & Fabrication Breakthroughs

A European microfabrication laboratory recently unveiled a wafer-level vacuum packaging process tailored for MEMS gyroscopes, achieving an internal cavity pressure of 1 mTorr-100 times lower than standard packaging techniques. As published in Sensors and Actuators A: Physical (2025), this breakthrough reduces mechanical noise by 45%, enabling more accurate motion detection in high-vibration environments (e.g., autonomous vehicle chassis). Separately, a North American semiconductor firm developed a eutectic bonding method for MEMS dies that improves long-term stability: device drift rates decreased by 30% after 10,000 hours of operation, compared to conventional adhesive bonding.

Practical Application Examples

In commercial drones, MEMS IMUs have elevated hover accuracy to ±5 cm-70% better than older sensor setups-while extending flight time by 20% due to reduced power draw, according to Drone Industry Insights (2025). For autonomous trucks, IMUs integrated with GPS/INS (Inertial Navigation Systems) provide position updates every 1 ms, ensuring continuous navigation even in GPS-denied zones (e.g., tunnels or urban canyons). In medical devices, MEMS IMUs in robotic surgical tools enable sub-millimeter movement tracking, reducing procedure error rates by 18% compared to fiber-optic-based systems (Journal of Medical Robotics Research, 2025).

Reliability & Calibration Challenges

Temperature sensitivity remains a critical limitation: MEMS IMUs exhibit a drift rate of 0.5°/hr per °C, requiring frequent in-field calibration that adds 10% to maintenance costs for industrial equipment (IHS Markit, 2025). Long-term reliability also poses hurdles: a 2025 automotive component study found that 8% of MEMS IMUs show a 20% degradation in gyroscope accuracy after 5,000 hours of operation-well below the 10,000-hour lifespan required for automotive safety systems. Additionally, high-precision MEMS IMUs (bias instability <0.05°/hr) cost 300 per unit, 5–10 times more than low-grade alternatives, limiting adoption in cost-sensitive consumer electronics.

MEMS IMUs (Inertial Measurement Units) with 6-axis configuration-integrating 3-axis gyroscopes and 3-axis accelerometers-deliver significant performance gains over traditional mechanical or fiber-optic alternatives. Per STMicroelectronics' 2025 Product Datasheet, these devices achieve a bias instability of 0.1°/hr, a 90% reduction compared to mechanical gyroscopes, and operate at just 5 mW of power-80% lower than fiber-optic IMUs. This combination of precision and energy efficiency makes them ideal for battery-powered or space-constrained systems.

Design & Fabrication Breakthroughs

A European microfabrication laboratory recently unveiled a wafer-level vacuum packaging process tailored for MEMS gyroscopes, achieving an internal cavity pressure of 1 mTorr-100 times lower than standard packaging techniques. As published in Sensors and Actuators A: Physical (2025), this breakthrough reduces mechanical noise by 45%, enabling more accurate motion detection in high-vibration environments (e.g., autonomous vehicle chassis). Separately, a North American semiconductor firm developed a eutectic bonding method for MEMS dies that improves long-term stability: device drift rates decreased by 30% after 10,000 hours of operation, compared to conventional adhesive bonding.

Practical Application Examples

In commercial drones, MEMS IMUs have elevated hover accuracy to ±5 cm-70% better than older sensor setups-while extending flight time by 20% due to reduced power draw, according to Drone Industry Insights (2025). For autonomous trucks, IMUs integrated with GPS/INS (Inertial Navigation Systems) provide position updates every 1 ms, ensuring continuous navigation even in GPS-denied zones (e.g., tunnels or urban canyons). In medical devices, MEMS IMUs in robotic surgical tools enable sub-millimeter movement tracking, reducing procedure error rates by 18% compared to fiber-optic-based systems (Journal of Medical Robotics Research, 2025).

Reliability & Calibration Challenges

Temperature sensitivity remains a critical limitation: MEMS IMUs exhibit a drift rate of 0.5°/hr per °C, requiring frequent in-field calibration that adds 10% to maintenance costs for industrial equipment (IHS Markit, 2025). Long-term reliability also poses hurdles: a 2025 automotive component study found that 8% of MEMS IMUs show a 20% degradation in gyroscope accuracy after 5,000 hours of operation-well below the 10,000-hour lifespan required for automotive safety systems. Additionally, high-precision MEMS IMUs (bias instability <0.05°/hr) cost 300 per unit, 5–10 times more than low-grade alternatives, limiting adoption in cost-sensitive consumer electronics.