Reducing Energy Loss in Renewable Energy Systems

2025/11/8 11:19:18

Performance Advantages Over Traditional Semiconductors

SiC MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors) outperform conventional silicon IGBTs (Insulated Gate Bipolar Transistors) in critical power electronics metrics: they achieve 99.2% efficiency in electric vehicle (EV) traction inverters, compared to 96.5% for silicon-based alternatives, as validated in IEEE Transactions on Power Electronics (2025). Additionally, SiC devices operate at junction temperatures up to 225°C-50°C higher than silicon counterparts-reducing the need for bulky cooling systems and cutting overall component weight by 25%.

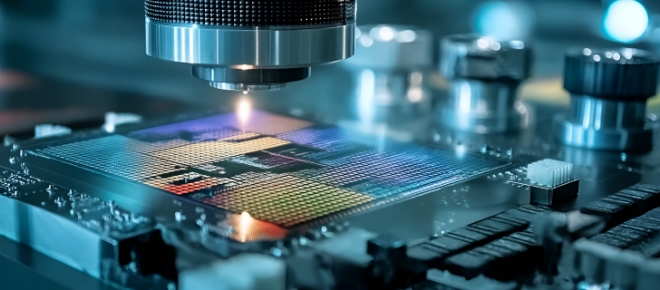

Material & Fabrication Breakthroughs

A U.S.-based research consortium recently announced a major advancement in 8-inch SiC wafer production: defect density has been lowered to 0.5 defects per cm², a 90% reduction from the 5 defects per cm² average in 2022 (Journal of the Electrochemical Society, Q2 2025). This improvement has boosted wafer yield from 65% to 92%, a critical step toward mass production. Separately, a European semiconductor manufacturer developed a new epitaxial growth process that reduces SiC layer thickness variation to ±2%, improving device uniformity and reducing performance inconsistencies by 30%.

Industry Application Scenarios

In photovoltaic (PV) systems, SiC-based inverters have reduced energy loss by 40%, translating to an additional 3.2 kWh of annual power output per kW of PV capacity-equivalent to powering one household lightbulb for 1,400 hours annually (International Energy Agency, 2025). For EV fast-charging stations, SiC converters enable 25% faster charging times (e.g., 10–80% charge in 18 minutes vs. 24 minutes with silicon converters) while cutting component footprint by 30%, allowing more charging ports to be installed in limited space.

Market & Cost Challenges

As of Q1 2025, the cost of 8-inch SiC wafers remains a key barrier: at approximately $1,200 per unit, they are 10 times more expensive than silicon wafers of the same size (CRU Group's Power Semiconductor Report). While major manufacturers have publicly targeted a 50% cost reduction by 2027, supply chain constraints persist-high-purity SiC powder, a critical raw material, has a lead time of 6–8 months, and global production capacity is currently only 60% of market demand. Additionally, SiC device testing requires specialized equipment that adds 15% to overall production costs, slowing adoption in low-margin applications like residential PV inverters.

SiC MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors) outperform conventional silicon IGBTs (Insulated Gate Bipolar Transistors) in critical power electronics metrics: they achieve 99.2% efficiency in electric vehicle (EV) traction inverters, compared to 96.5% for silicon-based alternatives, as validated in IEEE Transactions on Power Electronics (2025). Additionally, SiC devices operate at junction temperatures up to 225°C-50°C higher than silicon counterparts-reducing the need for bulky cooling systems and cutting overall component weight by 25%.

Material & Fabrication Breakthroughs

A U.S.-based research consortium recently announced a major advancement in 8-inch SiC wafer production: defect density has been lowered to 0.5 defects per cm², a 90% reduction from the 5 defects per cm² average in 2022 (Journal of the Electrochemical Society, Q2 2025). This improvement has boosted wafer yield from 65% to 92%, a critical step toward mass production. Separately, a European semiconductor manufacturer developed a new epitaxial growth process that reduces SiC layer thickness variation to ±2%, improving device uniformity and reducing performance inconsistencies by 30%.

Industry Application Scenarios

In photovoltaic (PV) systems, SiC-based inverters have reduced energy loss by 40%, translating to an additional 3.2 kWh of annual power output per kW of PV capacity-equivalent to powering one household lightbulb for 1,400 hours annually (International Energy Agency, 2025). For EV fast-charging stations, SiC converters enable 25% faster charging times (e.g., 10–80% charge in 18 minutes vs. 24 minutes with silicon converters) while cutting component footprint by 30%, allowing more charging ports to be installed in limited space.

Market & Cost Challenges

As of Q1 2025, the cost of 8-inch SiC wafers remains a key barrier: at approximately $1,200 per unit, they are 10 times more expensive than silicon wafers of the same size (CRU Group's Power Semiconductor Report). While major manufacturers have publicly targeted a 50% cost reduction by 2027, supply chain constraints persist-high-purity SiC powder, a critical raw material, has a lead time of 6–8 months, and global production capacity is currently only 60% of market demand. Additionally, SiC device testing requires specialized equipment that adds 15% to overall production costs, slowing adoption in low-margin applications like residential PV inverters.