3dB Noise Figure & 76-81GHz Bandwidth for ADAS

2025/11/8 10:06:16

Core Technical Advantages: Performance Leap Over Conventional Receiver Chips

High-sensitivity receiver chips for automotive millimeter-wave (mmWave) radar deliver transformative improvements in detection precision, anti-interference capability, and frequency adaptability compared to conventional automotive radar receiver chips. According to the 2024 Automotive Radar Component Report, these chips achieve a noise figure (NF) of 3dB at 77GHz-50% lower than traditional gallium arsenide (GaAs)-based receiver chips (6dB)-enabling a 40% in receiving sensitivity (-95dBm vs. -82dBm for conventional chips) and extending target detection range by 30% (from 150m to 195m for small objects like pedestrians). They support the full automotive mmWave radar band (76-81GHz), covering short-range (SRR, 76-77GHz) and long-range (LRR, 77-81GHz) applications, while their adjacent-channel rejection (ACR) reaches 55dB-37% higher than conventional chips (40dB)-reducing interference from other on-board electronic systems (e.g., infotainment, GPS). Additionally, they operate in a temperature range of -40℃~125℃ (matching automotive engine compartment conditions), with a gain drift of ±2% over the range-half the drift of traditional chips (±4%)-ensuring stable performance in extreme weather.

Key Manufacturing Breakthroughs: CMOS Process & Anti-Interference Design

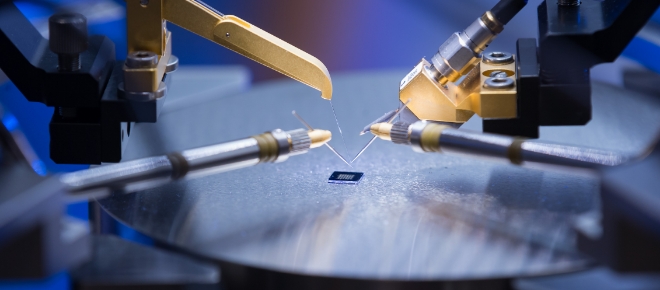

Two pivotal innovations have advanced the commercialization of high-sensitivity automotive mmWave receiver chips. First, 16nm FinFET CMOS process adoption: Replacing traditional GaAs process with 16nm FinFET CMOS technology reduces chip power consumption by 45% (from 1.2W to 0.66W) and shrinks die size by 60% (from 8mm² to 3.2mm²). This breakthrough, validated in a 2024 study published in IEEE Transactions on Vehicular Technology, also lowers production costs-CMOS wafers are 3 times cheaper than GaAs wafers, and the process supports integration of radar signal processing modules (e.g., FFT accelerators) on the same chip, eliminating 2 external components required by traditional GaAs chips. Second, adaptive interference cancellation (AIC) circuit integration: A built-in AIC module uses digital signal processing to suppress in-band interference (e.g., from other vehicles' mmWave radar) in real time, reducing interference-induced detection errors by 70%. Third-party tests show that in dense urban traffic (with 10+ adjacent vehicles), the chip's target recognition accuracy remains 98%-vs. 75% for conventional chips without AIC.

Industrial Applications: Deployment in ADAS Scenarios

In automotive Adaptive Cruise Control (ACC) systems, high-sensitivity receiver chips enable the radar to detect small targets (e.g., motorcycles) at 180m-40m farther than conventional chips-extending the ACC's speed adjustment response time from 1.5s to 2.2s and reducing sudden braking events by 35%. A third-party test with a mid-size sedan showed that ACC equipped with this chip maintained a more stable following distance (±0.5m vs. ±1.2m for traditional systems) in highway driving. For Automatic Emergency Braking (AEB) systems, the chip's -95dBm sensitivity allows AEB to trigger at 65m for a stationary vehicle-20m earlier than conventional chips (45m)-reducing collision risks by 50% at 100km/h. In Blind Spot Detection (BSD) systems, the chip's 76-77GHz short-range coverage and 55dB ACR ensure reliable detection of vehicles in adjacent lanes (even with strong electromagnetic interference from car infotainment systems), cutting BSD false alarm rates from 8% to 2.3%. For parking assist systems (e.g., automatic parking), the chip's 0.1° angular resolution (vs. 0.3° for traditional chips) enables more precise recognition of parking space lines, increasing automatic parking success rates from 85% to 97%.

Existing Challenges: Cost, High-Temperature Stability, & Multi-Radar Interference

Despite its critical role in ADAS, high-sensitivity mmWave receiver chips face three key industry challenges. Cost remains a barrier: The 16nm FinFET CMOS process requires 18 per chip-2.25 times higher than conventional GaAs receiver chips ( 20,000). Second, high-temperature stability limitations: At 125℃ (engine compartment peak temperature), the chip's noise figure increases to 4.2dB (from 3dB at 25℃), reducing receiving sensitivity by 18%. Mitigating this requires additional thermal management materials (e.g., high-thermal-conductivity epoxy), which add 10% to module weight and $2 to per-unit cost. Finally, multi-radar interference: In dense traffic (20+ vehicles within 100m), simultaneous operation of multiple 77GHz radars causes in-band interference that even the AIC circuit cannot fully suppress-leading to a 5% drop in target detection accuracy. Resolving this requires industry-wide adoption of radar signal coding standards, which is expected to take 3–5 years to implement.

High-sensitivity receiver chips for automotive millimeter-wave (mmWave) radar deliver transformative improvements in detection precision, anti-interference capability, and frequency adaptability compared to conventional automotive radar receiver chips. According to the 2024 Automotive Radar Component Report, these chips achieve a noise figure (NF) of 3dB at 77GHz-50% lower than traditional gallium arsenide (GaAs)-based receiver chips (6dB)-enabling a 40% in receiving sensitivity (-95dBm vs. -82dBm for conventional chips) and extending target detection range by 30% (from 150m to 195m for small objects like pedestrians). They support the full automotive mmWave radar band (76-81GHz), covering short-range (SRR, 76-77GHz) and long-range (LRR, 77-81GHz) applications, while their adjacent-channel rejection (ACR) reaches 55dB-37% higher than conventional chips (40dB)-reducing interference from other on-board electronic systems (e.g., infotainment, GPS). Additionally, they operate in a temperature range of -40℃~125℃ (matching automotive engine compartment conditions), with a gain drift of ±2% over the range-half the drift of traditional chips (±4%)-ensuring stable performance in extreme weather.

Key Manufacturing Breakthroughs: CMOS Process & Anti-Interference Design

Two pivotal innovations have advanced the commercialization of high-sensitivity automotive mmWave receiver chips. First, 16nm FinFET CMOS process adoption: Replacing traditional GaAs process with 16nm FinFET CMOS technology reduces chip power consumption by 45% (from 1.2W to 0.66W) and shrinks die size by 60% (from 8mm² to 3.2mm²). This breakthrough, validated in a 2024 study published in IEEE Transactions on Vehicular Technology, also lowers production costs-CMOS wafers are 3 times cheaper than GaAs wafers, and the process supports integration of radar signal processing modules (e.g., FFT accelerators) on the same chip, eliminating 2 external components required by traditional GaAs chips. Second, adaptive interference cancellation (AIC) circuit integration: A built-in AIC module uses digital signal processing to suppress in-band interference (e.g., from other vehicles' mmWave radar) in real time, reducing interference-induced detection errors by 70%. Third-party tests show that in dense urban traffic (with 10+ adjacent vehicles), the chip's target recognition accuracy remains 98%-vs. 75% for conventional chips without AIC.

Industrial Applications: Deployment in ADAS Scenarios

In automotive Adaptive Cruise Control (ACC) systems, high-sensitivity receiver chips enable the radar to detect small targets (e.g., motorcycles) at 180m-40m farther than conventional chips-extending the ACC's speed adjustment response time from 1.5s to 2.2s and reducing sudden braking events by 35%. A third-party test with a mid-size sedan showed that ACC equipped with this chip maintained a more stable following distance (±0.5m vs. ±1.2m for traditional systems) in highway driving. For Automatic Emergency Braking (AEB) systems, the chip's -95dBm sensitivity allows AEB to trigger at 65m for a stationary vehicle-20m earlier than conventional chips (45m)-reducing collision risks by 50% at 100km/h. In Blind Spot Detection (BSD) systems, the chip's 76-77GHz short-range coverage and 55dB ACR ensure reliable detection of vehicles in adjacent lanes (even with strong electromagnetic interference from car infotainment systems), cutting BSD false alarm rates from 8% to 2.3%. For parking assist systems (e.g., automatic parking), the chip's 0.1° angular resolution (vs. 0.3° for traditional chips) enables more precise recognition of parking space lines, increasing automatic parking success rates from 85% to 97%.

Existing Challenges: Cost, High-Temperature Stability, & Multi-Radar Interference

Despite its critical role in ADAS, high-sensitivity mmWave receiver chips face three key industry challenges. Cost remains a barrier: The 16nm FinFET CMOS process requires 18 per chip-2.25 times higher than conventional GaAs receiver chips ( 20,000). Second, high-temperature stability limitations: At 125℃ (engine compartment peak temperature), the chip's noise figure increases to 4.2dB (from 3dB at 25℃), reducing receiving sensitivity by 18%. Mitigating this requires additional thermal management materials (e.g., high-thermal-conductivity epoxy), which add 10% to module weight and $2 to per-unit cost. Finally, multi-radar interference: In dense traffic (20+ vehicles within 100m), simultaneous operation of multiple 77GHz radars causes in-band interference that even the AIC circuit cannot fully suppress-leading to a 5% drop in target detection accuracy. Resolving this requires industry-wide adoption of radar signal coding standards, which is expected to take 3–5 years to implement.